Shaping an Eco-Friendly Future with Advanced Materials

- 社会责任

- Contact Us

- 宣传中心

- CN

-

HYOSUNG ADVANCED MATERIALS LOGO

ESG Now

Shaping an Eco-Friendly Future with Advanced Materials

The acceleration of global warming is causing a rapid depletion of Earth's water resources, resulting in food shortages due to drought. Furthermore, rising sea levels are causing cities to disappear, and the number of extinct species is increasing, which is disrupting the chain of life. This climate crisis is undoubtedly the most significant environmental issue, and it has become a global concern. Corporations now have an increased responsibility towards the environment.

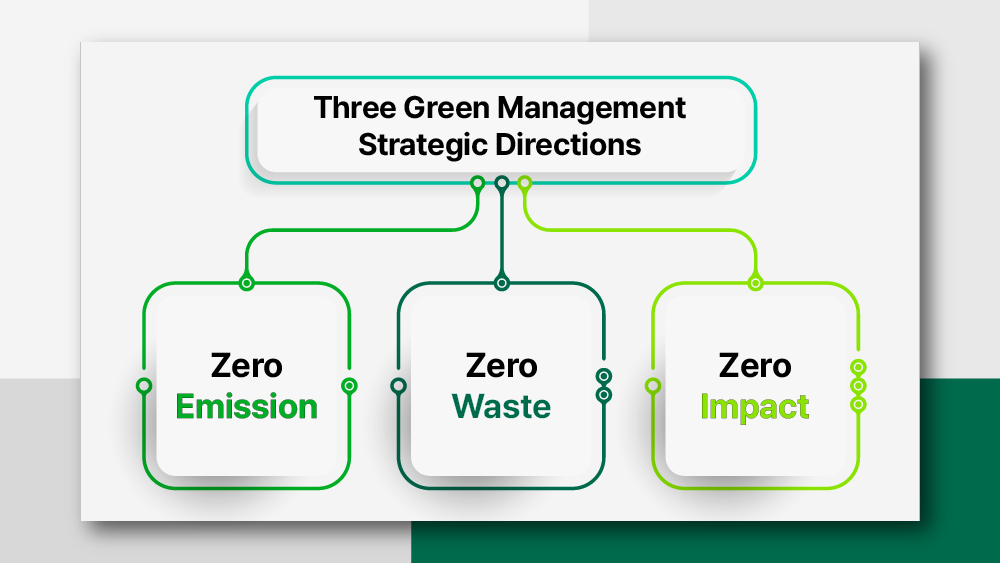

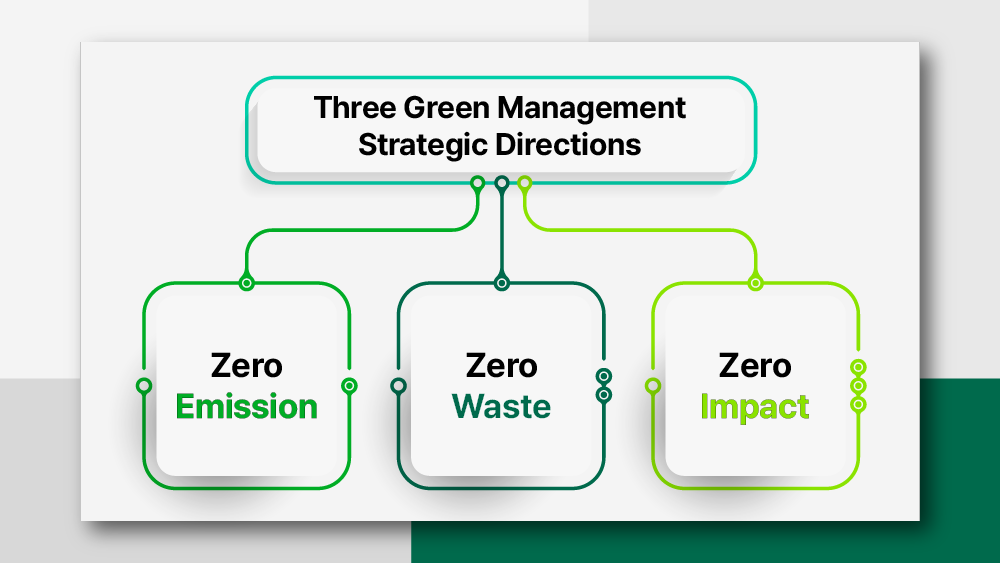

At Hyosung Advanced Materials, we take our societal responsibilities seriously, especially when it comes to the looming climate crisis. Our mission is to create a safe and clean environment that fosters human sustainability and promotes happiness. To achieve this goal, we have adopted green management practices and joined the SBTi (Science Based Targets initiative) to develop a long-term roadmap for climate change. We are actively researching and producing sustainable material technologies that align with our three green management strategic directions: 'Zero Emission,' 'Zero Waste,' and 'Zero Impact.'

With a sense of responsibility towards humanity and the environment, Hyosung Advanced Materials is introducing eco-friendly solutions for safer and more sustainable materials, our Future Materials.

Efforts to Reduce Greenhouse Gases: Zero Emission

At Hyosung Advanced Materials, we are committed to achieving Zero Emission for carbon neutrality by reducing greenhouse gas emissions during our product production and use. Our focus is on developing lightweight products with low carbon footprint to help mitigate this issue. With the global push to reduce greenhouse gas emissions, the demand for electric and hydrogen vehicles that emit less carbon dioxide and reduce environmental pollution has increased. However, since these vehicles are heavier due to installed batteries, the importance of lightweighting has become more apparent to address efficiency issues.

To meet this demand, we are producing TANSOME®, a lightweight material and the first domestically developed carbon fiber. Carbon fiber is four times lighter than steel and over ten times stronger, making it an ideal material for lightweighting in various fields such as automotive, aerospace, wind turbine blades, civil engineering and construction, and sports equipment. Specifically, it's gaining attention as an eco-friendly future material as it aids in improving fuel efficiency and reducing carbon dioxide emissions when applied to CNG and hydrogen high-pressure tanks.

In addition, we have developed Ultra Tensile steel cords to reduce the weight of automobile tires. The higher the strength of steel cords, which serve as tire reinforcements, the lower the weight, leading to improved fuel efficiency and reduced carbon dioxide emissions. Currently, our Ultra Tensile steel cords are leading the lightweighting of automobiles, boasting the highest market share worldwide.

Hyosung Advanced Materials is not only committed to making cars lighter, but also to developing materials that help combat carbon emissions, a major contributor to global warming. One such material is our Lyocell tire cords, which are made from cellulose extracted from wood and can reduce greenhouse gas emissions by around 30% when compared to rayon or nylon. These cords are also environmentally friendly, as they release very few harmful substances such as sulfur dioxide and hydrogen sulfide, which helps prevent both air and water pollution. All four types of tire cord products produced by Hyosung Advanced Materials, including Lyocell, have received carbon labeling certification. We are planning to obtain additional certifications for a total of 23 products from eight domestic and international businesses.

Creating a Cycle for Discarded Resources: Zero Waste

At Hyosung Advanced Materials, we are dedicated to achieving Zero Waste by conserving resources used in production. Our commitment has led us to develop high-strength Recycled PET yarn, utilizing resources that would otherwise be discarded. This sustainable material has been awarded the Global Recycled Standard (GRS) certification from an international eco-friendly certification institution. Our Recycled PET yarn is available in two categories: Mechanical Recycled yarn and Chemical Recycled yarn. The former is created by reprocessing crushed waste PET bottles into small flakes or pellet shapes, while the latter is produced by collecting waste plastic, converting it into BHET (recycled raw material) through depolymerization equipment, and then manufacturing PET.

There are two types of yarns used for fiber tire cords, which are crucial in maintaining the shape and durability of tires. These yarns are also utilized in creating life-saving airbags, seatbelt yarns, comfortable automobile carpet yarns, and sewing threads for clothing and shoes. Our company has also innovated vehicle mats using recycled Bulked Continuous Filament (BCF) and is currently assessing its feasibility for commercialization. Our efforts in resource conservation and recycling are diverse and ongoing.

Healthier and Environmentally Friendly from the Production Stage: Zero Impact

At Hyosung Advanced Materials, we offer a range of solutions to achieve Zero Impact, while also reducing greenhouse gases and promoting resource recycling. Our goal is to minimize the negative impact on the environment throughout the entire process, from raw materials to production, usage, and post-use treatment. We are committed to eco-friendly production and make significant efforts towards achieving this.

Our primary goal is to achieve Zero Impact by shifting to sustainable raw materials. We are currently working on creating Bio-PET yarn with Bio-EG sourced from natural materials. By producing Bio-based PET yarn with Bio-EG extracted from sugarcane and corn, instead of petroleum-based Ethylene glycol (EG) typically used for polyester, we can substantially diminish greenhouse gas emissions and energy consumption in comparison to traditional production methods.

At Hyosung Advanced Materials, we're proud to use Bio-PET yarn in our production process for fiber tire cords, airbags, seatbelt yarns, and automobile carpets. This innovative material helps us address both resource waste and environmental concerns. We're especially thrilled to have achieved the world's first International Sustainability & Carbon Certification (ISCC) PLUS certification for our eco-friendly processes, which incorporate Bio-Based PET, Mechanical Recycled PET, and Chemical Recycled PET.

Hyosung Advanced Materials has earned the ISCC certification due to our commitment to eco-friendly manufacturing practices that result in Zero Impact. In the production of tire cords, we utilize a chemical adhesive that is both eco-friendly and free of formalin, a harmful component commonly found in such adhesives. Our efforts to create sustainable processes extend to the production of steel cords as well. For instance, we have introduced electric furnace wire rods as a replacement for blast furnaces, thereby reducing carbon emissions.

Hyosung Advanced Materials is a company dedicated to researching various materials that ensure our safety and protect our lives. They specialize in producing airbags, automobile tire reinforcements, and automotive seatbelt yarns, as well as developing new future materials. Thanks to their diverse technological capabilities, we are able to safely and comfortably maintain our precious everyday lives with their products.

Hyosung Advanced Materials is committed to safeguarding both our present and future. Not only does it protect our daily lives, but it also strives to safeguard the environment by developing sustainable materials. The company's technological prowess enables the realization of Zero Emission, Zero Waste, and Zero Impact without compromising our comfort and safety. As a result, we can ensure the safety of both ourselves and the planet.

Hyosung Advanced Materials has provided eco-friendly solutions that will help make our planet cleaner. We are committed to developing sustainable technologies that protect our current and future daily lives. Our efforts will never stop as we strive to prepare safe and clean material technologies to ensure a safe Earth for the next generation.