- Sustainability

- Contact Us

- PR Center

- EN

-

HS HYOSUNG ADVANCED MATERIALS LOGO

Tirecords

with solid technology

build trust throughout

the world

HS Hyosung Advanced Materials has been in the tire reinforcements business since 1968 when we became the first Korean

company to produce Nylon Tirecord. As well as PET Tirecord, we also began producing steel cord and Bead wire over

time and have grown into the global tire reinforcements industry’s largest company equipped with integrated production

and supply systems for tire reinforcements, earning the trust of customers all around the world. HS Hyosung Advanced

Materials is globally recognized for the quality and technological capabilities of our products. Our PET Tirecord in

particular has been maintaining the largest share of its respective global market, and our products are being supplied to the

world's leading tire manufacturers.

for tire reinforcement Total solution company

produced both tire reinforcement

HS Hyosung Advanced Materials produced the first Tirecords in Korea in 1968.

We have since evolved into the best company developing, producing, and supplying both textile and steel cords for tire reinforcement through great strides.

-

Textile cords for tire

Textile cords for tire

reinforcement PET, Nylon, Lyocell, Aramid, etc. -

Steel cords for tire

Steel cords for tire

reinforcement Steel cord, Bead wire, etc.

market share, PET Tirecord

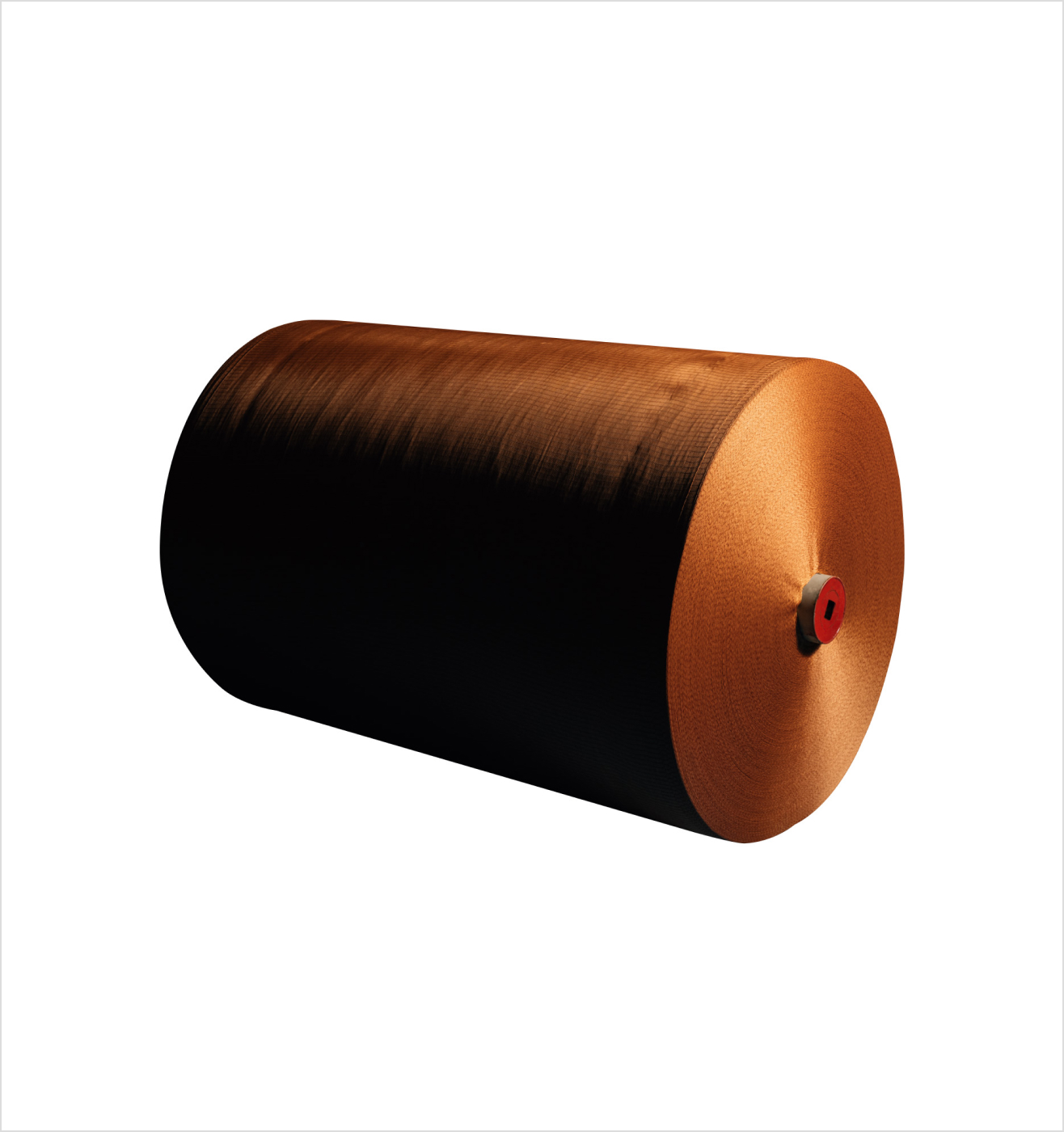

PET Tirecord is used as a raw materials of carcass which functions as the structure of tire, provide the strength to contain the inflation pressure and so on.

HS Hyosung Advanced Materials’ PET Tirecords are maintaining an unchallenged position as they are supplied to globally distinguished tire one out of two passenger cars in the world uses tire cord produced by HS Hyosung Advanced Materials, demonstrating our unrivaled position in the sector.

-

Able to supply high-quality products at

competitive prices with five factories in four

countries around the world

certifications

-

Acquired quality certifications (e.g. ISO,

IATF16949), as well as ISCC Plus

certification for the first time in Korea

the Tirecord industry

-

Producing Textile tire cords used in tires

including PET, Nylon, and Lyocell -

Provides personalized services for customers

through R&D, production, and supply to

customers based on our years of know-how

- Capply (Nylon Tirecord, etc.)

- Keeps the tire in shape

- Belt (steel cord)

- grants lateral stiffness

- Carcass (PET Tirecord, etc.)

- bears the load

- Bead wire

- keeps the tire attached to the rim

supplier

Our ultra-tensile (UT) steel cord is ranked first place in the global market share, and the development of new UT specifications is in progress with global tire manufacturers due to the rising demand for UT steel cords for lightweight tires resulting from the growing EV market.

-

UT Steel cord

Growing need for the development of new UT steel cords for lightweight tires

as the EV market expandsDeveloped UT steel cord with new specifications and

secured production technologyIncreased market share through the development of

new UT specifications

About the Products

-

PET Tirecord

PET TirecordHS Hyosung Advanced Materials’ PET Tirecord has outstanding dimensional stability and adhesion properties and is often used to reinforce the tires of passenger cars and light trucks.

HS Hyosung Advanced Materials is capable of developing and providing various high-modulus, low-shrinkage (HMLS) PET cords, and we are maintaining our position as number one in market share with our proprietary technologies.

Nylon TirecordNylon Tirecord is used for capply which suppresses the expansion of radial tires fitted on passenger cars and so on.

It is also used as carcass for bias tires fitted on trucks, buses, etc. and for special tires fitted on aircrafts and motorcycles.

Nylon Tirecord has excellent heat resistance and adhesion properties

-

Aramid & Hybrid Tirecord

Aramid & Hybrid TirecordHS Hyosung Advanced Materials offers Aramid Tirecord and Hybrid Tirecords primarily used in premium tires that require high performance.

Aramid Tirecords possess high strength and heat resistance due to HS Hyosung Advanced Materials’ superior technology.

Hybrid Tirecords, designed to maximize the advantages of each material, can be produced using various materials from HS Hyosung Advanced Materials and can be tailored according to customer performance requirements (modulus and tenacity).

-

Eco-friendly TirecordLyocell Tirecord | Bio-Based | Recycled

Eco-friendly TirecordLyocell Tirecord | Bio-Based | RecycledAs an eco-friendly company, HS Hyosung Advanced Materials develops and produces eco-friendly Tirecords that can replace conventional products.

-

Lyocell TirecordLyocell Tirecords are primarily used in premium tires that require high performance. They are eco-friendly from raw materials to manufacturing methods. Developed using HS Hyosung Advanced Materials’ proprietary technology, they are supplied to global tire manufacturers.

-

Bio-Based Tirecord

(Bio-Based PET, Bio-Based Nylon)

Bio-Based PET and Bio-Based Nylon Tirecords from HS Hyosung Advanced Materials use raw materials extracted from plants and have the advantage of reduced CO2 emissions compared to conventional products. -

Recycled PET TirecordHS Hyosung Advanced Materials has produced PET Tirecords using eco-friendly materials such as mechanical recycled PET and chemical Recycled PET which developed by it through the use of raw materials extracted from waste PET bottle.

Sustainable PET Tirecord will become a next generation eco-friendly product that can reduce the amount of landfill waste through recycling waste plastics.

-

Applications

-

Tire reinforcement materials for passenger carsCarcass, capply, and bead part reinforcement materials

-

Tire reinforcement materials for light trucksCarcass, capply, and bead part reinforcement materials

-

Tire reinforcement materials for trucks/busesBead part reinforcement materials, etc.

-

OthersReinforcing materials for OTR, Motorcycle, Bike, etc

About the Products

-

Steel cord

Steel cordSteel cord is a product that requires strict process control such as adhesion with rubber, strength, and fatigue resistance. It is a product often used for belts and carcasses of tires that enhances the tensile strength of tires, withstands impact from the surface of the road, functions as the framework of tires, and supports against the load imposed from the exterior.

HS Hyosung Advanced Materials’ steel cord is expanding its product range to high-strength products in line with the increase of electric vehicles. Also responding to customers' needs for eco-friendly products, recycled steel cord products are being developed and in the process of customer evaluation. In addition, the company is striving for technological advances in product development and production technologies.

-

Bead wire

Bead wireBead wire secures the carcass which withholds the internal pressure of the tire from the vehicle’s weight. It fastens the tire in place to the rim and is crucial in maneuvering drives, brakes, and steering torque to the road surface.

HS Hyosung Advanced Materials' Bead wire is produced in varied lengths and wire diameters and personalized accordingly to the customers’ needs.

Eco-friendly recycled Bead wire products have been developed to cater to eco-conscious needs of customers, providing immediate services to customers' specific requirements.

Applications

-

Steel cords for reinforcement of passenger car radial tiresBelt, Bead part

-

Steel cords for reinforcement of light truck radial tiresBelt, Bead part

-

Steel cords for reinforcement of truck & bus radial tiresBelt, Carcass, Chafer, Bead part

-

Steel cords for reinforcement of off-the-road (OTR) tiresBelt, Carcass, Bead part

Contact customer service for

any inquiries on our products.